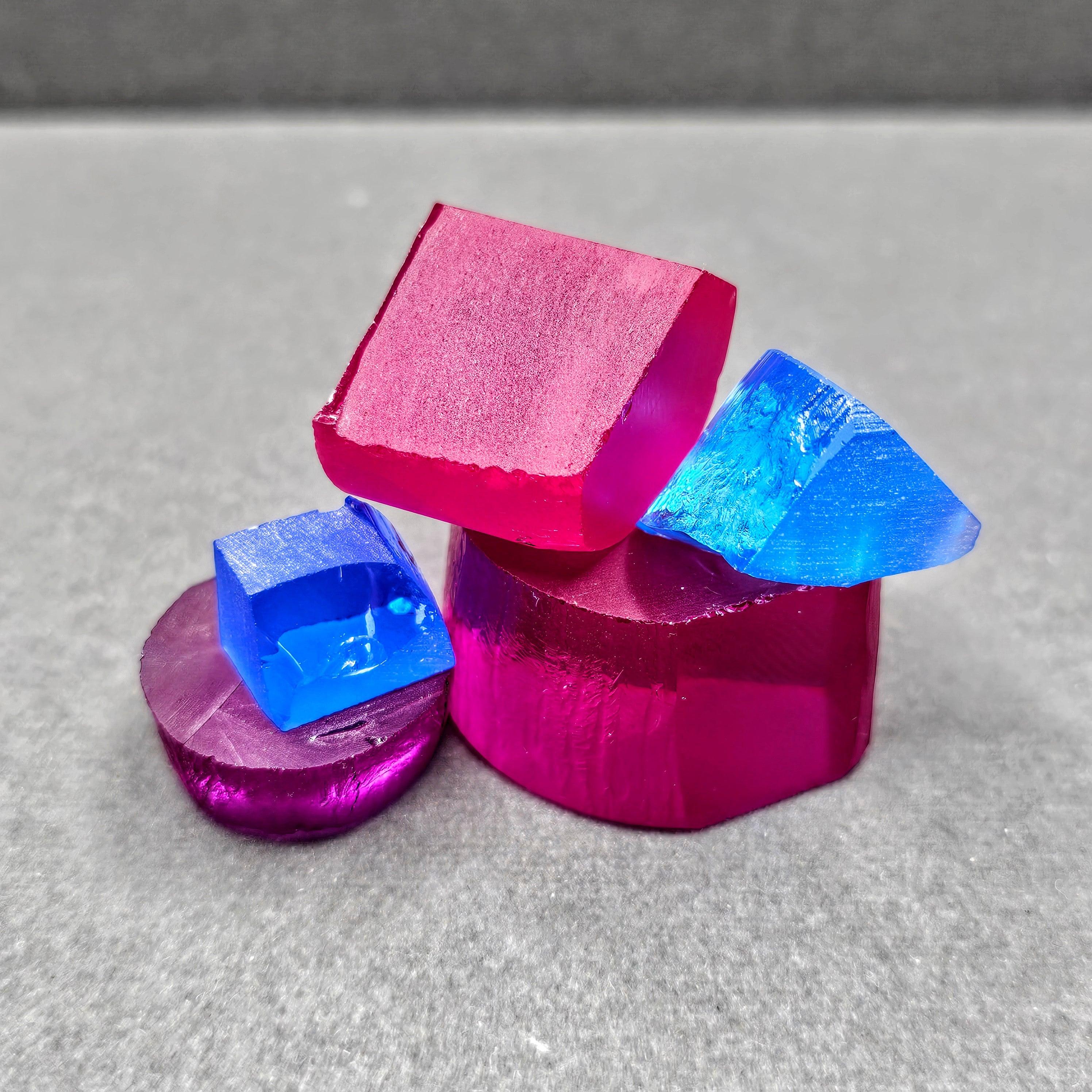

The Czochralski process, developed in 1916 by Polish scientist Jan Czochralski, is a method of crystal growth used to obtain single crystals of semiconductors (e.g., silicon, germanium and gallium arsenide), metals (e.g., palladium, platinum, silver, gold), salts, and synthetic gemstones. The method has been adapted to produce synthetic sapphire and ruby, which are varieties of the mineral corundum. Synthetic sapphire and ruby are created by melting aluminum oxide (with chromium added for ruby to give it its red color) in a crucible, and then a seed crystal is dipped into the molten bath and slowly withdrawn, promoting the growth of a large, cylindrical crystal of the desired material. This method allows for the precise control over the crystal's chemical composition, size, and orientation.

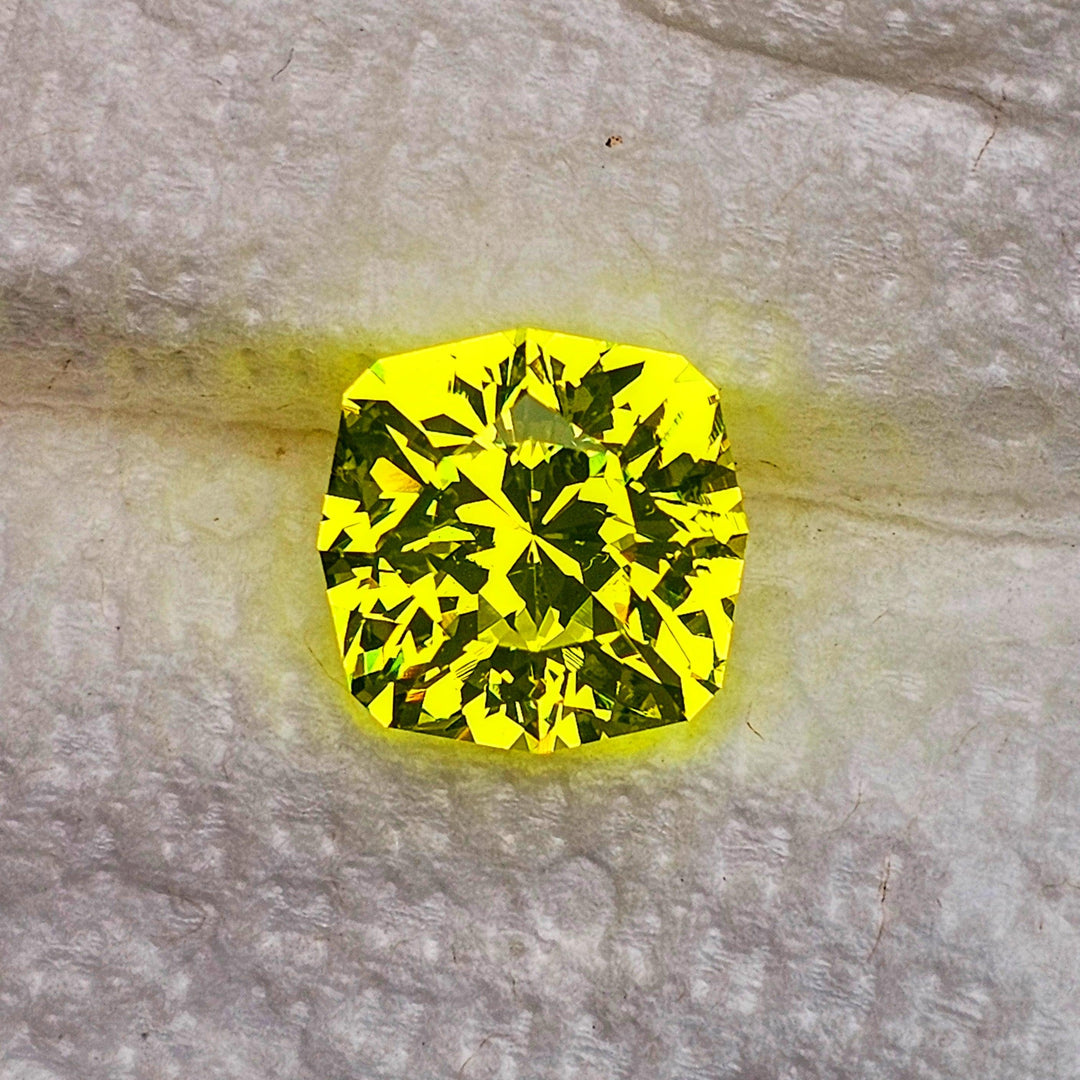

The synthetic sapphire and ruby produced via the Czochralski process have a wide range of applications. Due to their exceptional hardness (second only to diamonds), thermal conductivity, electrical insulating properties, and optical transparency across a wide range of wavelengths, synthetic sapphire is extensively used in the manufacture of substrates for semiconductor devices, watch crystals, laser components, and scratch-resistant windows and screens. Ruby, on the other hand, has found its niche in laser technology as the first material used to create a laser; the chromium ions in ruby can be excited to higher energy levels by light, and then they emit light of a characteristic wavelength, a principle that underlies the ruby laser's operation. Both materials, thanks to their durability and aesthetic appeal, are also popular in jewelry, serving as cost-effective alternatives to their natural counterparts.