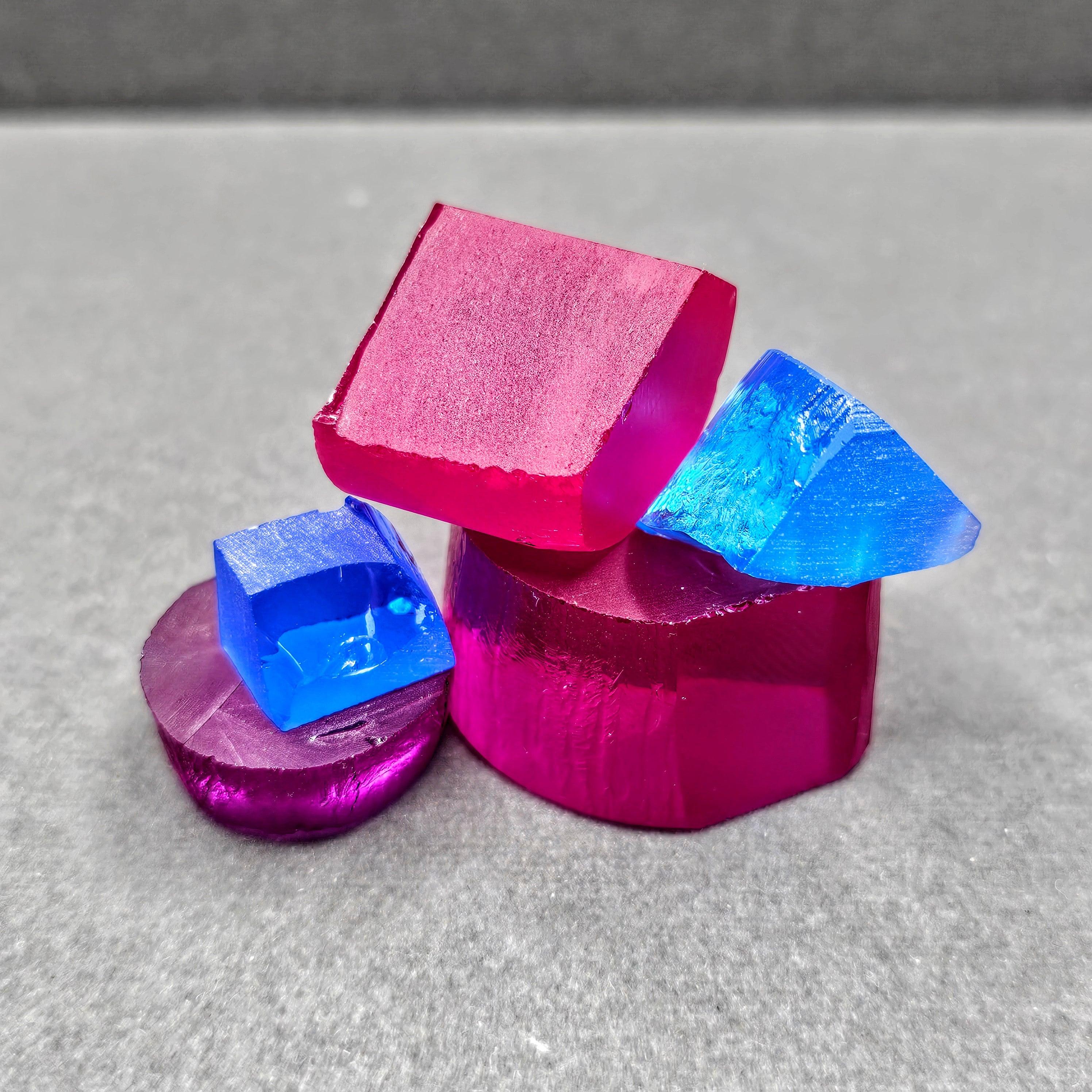

The Kyropoulos method, developed by Spyro Kyropoulos in the early 20th century, is a crystal growth technique predominantly used for producing large, high-quality single crystals, such as sapphire. In this method, a seed crystal is initially dipped into a crucible containing the molten material (like alumina for sapphire). Unlike other methods, the seed crystal is not pulled out but rather remains submerged. The temperature of the melt is gradually reduced, and the crystal grows in size as the material crystallizes around the seed. The key advantage of the Kyropoulos process is the ability to maintain a stable, low-stress environment, which is conducive to growing large and flawless crystals with minimal dislocations and internal strains. This makes it especially suitable for applications where crystal size and purity are critical, such as substrates for semiconductor wafers and various optical applications like watch covers and laser windows. The Kyropoulos method's efficiency in producing large-scale, high-quality crystals makes it a vital technique in advanced materials manufacturing.

🌍 Unearth the Excitement ♻️

🔥 New Items Added Daily! 🔥

📐Precision Cut: .25 micron polish